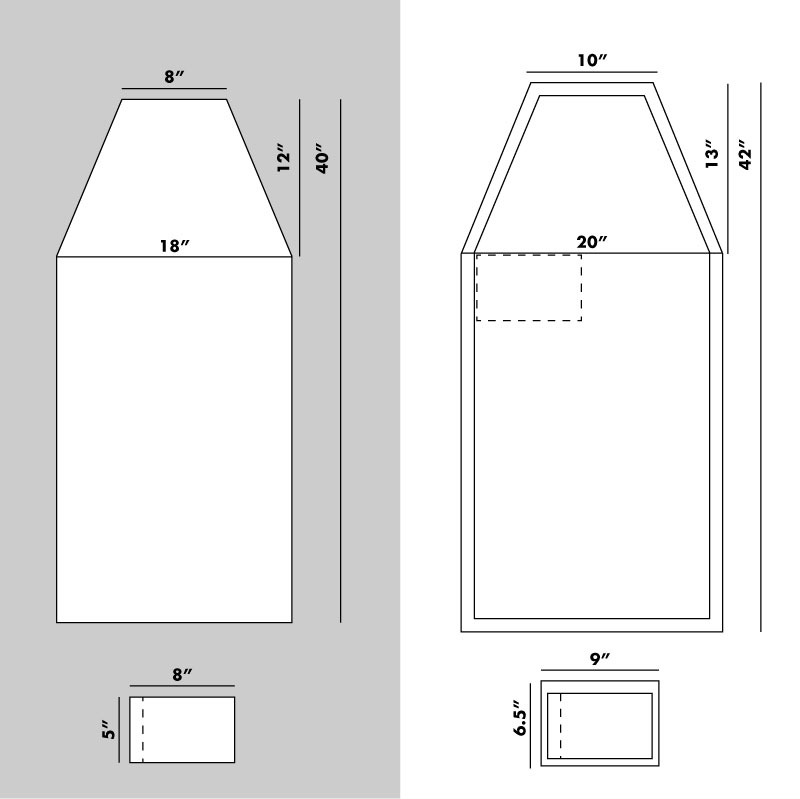

Brad's been working on the house non-stop since we moved in almost three years ago. I do what I can to help, but usually that means providing snacks and drinks and staying out of the way. Normally I'm very selfish when it comes to sewing. If I can't show it off, what's the point of spending hours hunched over the sewing machine?This shop apron for my handy hubby is the exception to my selfish sewing rule. It all started when I spotted 3.5 yards of this deep indigo denim material on the flat fold table at Hancock Fabrics (have you seen this section? I've found some ah-mazing stuff there and it's all $4.95 per yard.) The material has some stretch to it, and while that's going to be perfect for the Ginger jeans I plan on making soon, it's not exactly ideal for this apron since there's some waviness happening in the horizontal seams.(Side note: when buying new denim pre-wash it separately from other fabrics. Unless you like the slightly grayish blue tint it leaves behind on all the areas of your other fabrics that are supposed to be white. Apparently I don't.)The construction of the apron is fairly simple. I took a few quick measurements and drew them directly on the wrong side of the fabric, trying to go with the grain as much as possible by lining up the fold along the tiny twill lines.My initial measurements are on the left in the gray box and my measurements with seam allowance are on the right in the white box. I used a 1" seam allowance on each edge so the edge could be folded down 1/2", then turned under another 1/2" and top stitched. I measured just under the collarbone across the chest (8"), around the front of the waist to the side seams of his shirt (18"), from collarbone to waist (12") and from collarbone to below his knees (40").[responsive] [/responsive]The dashed line on the apron shows the pocket placement, the dashed line on the pocket shows a line of stitching to create a pencil pocket and the seam allowance is a little different on the pocket since the left, right and bottom edges were just turned under 1/2" then stitched down.[responsive]

[/responsive]The dashed line on the apron shows the pocket placement, the dashed line on the pocket shows a line of stitching to create a pencil pocket and the seam allowance is a little different on the pocket since the left, right and bottom edges were just turned under 1/2" then stitched down.[responsive] [/responsive]Please excuse the mess in the background...someday I'll get some fancy well-lit photos of this thing, but for now I'm just happy he let me photograph him in it.We tore apart an old point-and-shoot camera bag for the straps and hardware. Always save the hardware and zippers, even if you'll never use the bag and want to get rid of it! That stuff ain't cheap.The neck strap and D rings were sewn directly into the edge while I was top stitching. I had Brad put on the apron and we threaded the strap through the D rings, adjusted the length to his liking and snipped the strap. I stitched down the end of the strap to keep it from fraying and made a denim loop which I hand sewed about 3" above the D rings to keep the strap in place.The waist strap has a slider already on it, so we kept that and the buckle at the end and I just sewed a large metal ring into the other side to give the buckle something to clasp onto. I had originally planned on making all the straps out of denim (even going as far as making them and top stitching them) but as Brad was digging for D rings he found this old camera bag and we just went with it. Now I have denim straps left over...maybe a half apron for me? :)We also ended up chopping a few inches off the hem to make it easier to walk around. 40" makes a pretty long apron, but 35" seems to work well.[responsive]

[/responsive]Please excuse the mess in the background...someday I'll get some fancy well-lit photos of this thing, but for now I'm just happy he let me photograph him in it.We tore apart an old point-and-shoot camera bag for the straps and hardware. Always save the hardware and zippers, even if you'll never use the bag and want to get rid of it! That stuff ain't cheap.The neck strap and D rings were sewn directly into the edge while I was top stitching. I had Brad put on the apron and we threaded the strap through the D rings, adjusted the length to his liking and snipped the strap. I stitched down the end of the strap to keep it from fraying and made a denim loop which I hand sewed about 3" above the D rings to keep the strap in place.The waist strap has a slider already on it, so we kept that and the buckle at the end and I just sewed a large metal ring into the other side to give the buckle something to clasp onto. I had originally planned on making all the straps out of denim (even going as far as making them and top stitching them) but as Brad was digging for D rings he found this old camera bag and we just went with it. Now I have denim straps left over...maybe a half apron for me? :)We also ended up chopping a few inches off the hem to make it easier to walk around. 40" makes a pretty long apron, but 35" seems to work well.[responsive] [/responsive][responsive]

[/responsive][responsive] [/responsive][responsive]

[/responsive][responsive] [/responsive]I discovered a foot that really helped me get even top stitching: the blind stitch foot. It looks kind of like this:

[/responsive]I discovered a foot that really helped me get even top stitching: the blind stitch foot. It looks kind of like this: I used the blind hem guide in the middle with a straight stitch set at 3mm to slowly sew along the edge of the fabric, then did a second line using the right edge of the foot as a guide. It seemed to work pretty well and it's good to figure these things out before moving on to actual jeans.Anyway, there it is! I foresee this shop apron getting lots of use and hopefully Brad with naturally age it by spilling bleach and get dust on IT instead of on his clothes. Fingers crossed.Are there any presser feet that you've found to be really helpful, even if you don't use it for its intended purpose?

I used the blind hem guide in the middle with a straight stitch set at 3mm to slowly sew along the edge of the fabric, then did a second line using the right edge of the foot as a guide. It seemed to work pretty well and it's good to figure these things out before moving on to actual jeans.Anyway, there it is! I foresee this shop apron getting lots of use and hopefully Brad with naturally age it by spilling bleach and get dust on IT instead of on his clothes. Fingers crossed.Are there any presser feet that you've found to be really helpful, even if you don't use it for its intended purpose?

top stitching